CPP Metallised Film

Low initial heat sealing temperature

Softness

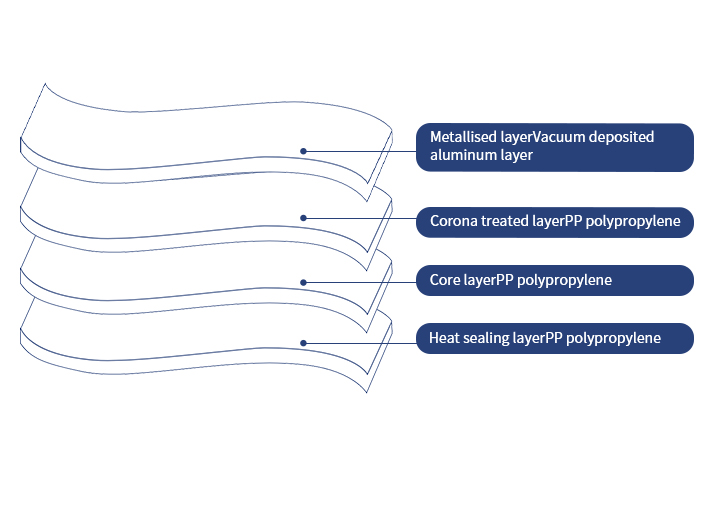

Excellent barrier property

Food contact grade

Product Advantages

Category

| Product catalogue | Product type |

|---|---|

| CPP metallised film | AlMCPP |

| Low initial heat sealing temperature metallised film with high bonding strength | ALML2/ALML3/ALML4/ALML5 |

| Semi-metallised CPP film | AlMCPP |

| Degradable CPP film metallised film | AlMODCPP |

| 高阻隔型 | ALM3-A/ALM4-A |

| 高阻隔增强型 | ALML2-A/ALML3-A/ALML4-A/ALML5-A |

| 低摩擦型 | ALMSCPP2/ALMLS2/ALMLS3 |

| 中摩擦型 | ALMLM2-A |

PS: The above CPP metallised film can be customized for clients according to their specific application demand.

Performance

| CPP metallised film( ALM2) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Property | Unit | Typical Values | Reference | Method | ||||

| Thickness | μm | 20.0 | 25.0 | 30.0 | 40.0 | ±3% | GB/T 6672 | |

| Density | g/cm3 | 0.89 | 0.89 | 0.89 | 0.89 | ±2% | GB/T 1033.1 | |

| Weight | g/m2 | 17.8 | 22.3 | 26.7 | 35.6 | ±2% | GB/T 6672 | |

| Yield | m2/kg | 56.2 | 44.9 | 37.5 | 28.1 | ±2% | GB/T 6672 | |

| Tensile strength | MD | MPa | 60.0 | 58.0 | 56.0 | 54.0 | ≥35 | GB/T 1040.3 |

| TD | MPa | 34.0 | 33.5 | 33.0 | 32.5 | ≥25 | GB/T 1040.3 | |

| Elongation at break | MD | % | 480 | 500 | 540 | 560 | ≥350 | GB/T 1040.3 |

| TD | % | 550 | 580 | 600 | 620 | ≥450 | GB/T 1040.3 | |

| wetting tension | Metallised side | mN/m | 38 | 38 | 38 | 38 | ≥36 | GB/T 14216 |

| Non-metallised side | mN/m | <33 | <33 | <33 | <33 | <33 | GB/T 14216 | |

| Coefficient of Friction | Non-metallised side | - | 0.80 | 0.75 | 0.70 | 0.70 | ≤0.90 | GB/T 10006 |

| Heat sealing range(Remark 1) | °C | 120 | 120 | 120 | 120 | ≤125 | GB/T 27740 | |

| Metallising layer thickness | Optical density | - | 2.0 | 2.0 | 2.0 | 2.0 | ≥1.8 | ASTM D 1003 |

| Square electrical resistance | Ω/☐ | 2.35 | 2.35 | 2.35 | 2.35 | ≤2.70 | GB/T 15717 | |

| Uniform metallised layer | % | 10.0 | 10.0 | 10.0 | 10.0 | ≤15.0 | GB/T 15717 | |

| Excellent metal adhesion | N/15mm | 0.3 | 0.3 | 0.3 | 0.3 | - | WF Method | |

| Oxygen transmission rate | cm3/m2.24h | 70.0 | 60.0 | 55.0 | 55.0 | - | GB/T 19789 | |

| Water vapor transmission rate | g/m2.24h | 0.5 | 0.45 | 0.4 | 0.4 | ≤0.8 | GB/T 26253 | |

| Thickness | Sealing strength |

|---|---|

| <40um | ≥8N |

| 20um | ≥7N |

| ≥40um | ≥12N |

The information on Weifu products and their applications provided in this datasheet is based on testing of representative material and the results are believed to be reliable as at the date of publication advised below. The information does not constitute a warranty or guarantee, either expressly or implied, of any specific product attribute or the suitability of products for specific applications. For particular technical requirements or specifications, please contact Weifu.

Application

Dry laminated with BOPP, PET and other materials. Suitable for automatic packaging machine, food and daily necessities packaging.